2023-02-24

2023-02-24If you operate a coal-burning company, would you like to choose $60 alternative fuels per ton or $180 coal fuels per ton?

Of course, such a direct comparison is not reasonable because alternative fuels differ from coal in terms of calorific value of combustion and disposal costs. Let us then calculate the actual economic benefits of alternative fuels compared to fossil fuels (as represented by coal) when the carbon reduction benefits are set aside.

The essence of fuel is to provide heat. Many places in the industry now already use the price per unit of calorific value of fuel to calculate, which is much more scientific!

Assuming a conventional 6,000 calorie coal price of $180, this would be $30 per 1,000 calories.

Alternative fuels made from biomass, industrial solid waste, municipal solid waste, etc. vary greatly in calorific value per unit, and the price varies accordingly. Roughly speaking, if the average calorific value of 4000 calories is $70, then 1000 calories is $17.5.

(30-17.5)/30=42.7%

Is the price of alternative fuels 42.7% lower than the price of coal? No, actually it's not finished.

Heat Loss Coefficient Ratio

Alternative fuels made from different solid waste materials and different preparation technologies have very different heat loss and burn-up rates compared to coal, which can be calculated together as a heat loss factor ratio, generally 1.15. Some high-quality alternative fuels can achieve less than 1, which is even better than coal (e.g. alternative fuels made from waste tires).

Pre-treatment Costs

There are labor costs and equipment costs associated with the preparation of alternative fuels, and the cost of these pre-treatments is around 10%.

The actual 1000 calorie alternative fuel would then be $17.5 x (heat loss factor ratio 1.15 + treatment cost 0.1) which equals approximately $22.

At this point, the difference in benefits of alternative fuels compared to coal is only 26%.

Although the above calculations are ideal, they also show that the economic benefits of alternative fuels can be improved by using better alternative fuel preparation technology and reducing the heat loss coefficient ratio, which can significantly increase the average calorific value of the alternative fuel.

Harden has studied the solid waste treatment industry in depth for more than ten years and has a total solution for solid recovered fuel (SRF) and refuse-derived fuel (RDF) preparation in the fields of municipal solid waste (MSW), bulky waste, paper mill waste, biomass waste, industrial solid waste, waste tires, agricultural and forestry waste, etc.

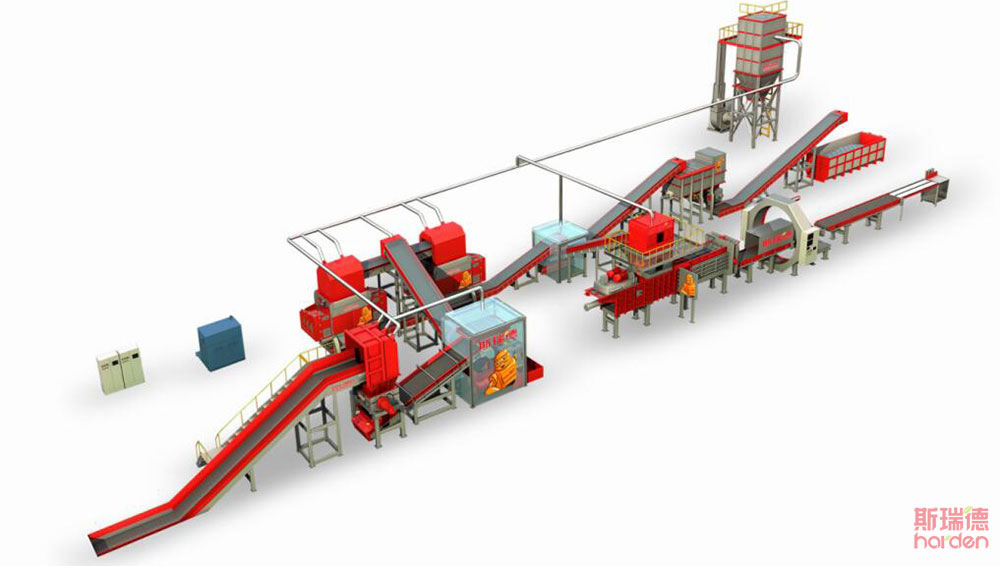

Alternative preparation system from industrial waste:

By integrating advanced solid waste shredding technology concepts and relying on the strength of continuous innovation in independent research and development, Harden's solid recovered fuels are better in terms of material size and impurity removal rate, with a lower heat loss coefficient and an average combustion calorific value of 4,800-5,200 calories through the process of secondary shredding, magnetic separation, air separation, sorting, dust removal and granulation.

Solid Recovered Fuel, Refuse-derived Fuel:

The main factors affecting the calorific value of combustion of alternative fuels are moisture content and discharge size.

1) Moisture content: Most alternative fuels have a moisture content of around 15%; The alternative fuels produced by Harden's alternative fuel technology contain less than 5% water. (Alternative fuels made from different materials can vary greatly in moisture content.)

2) Discharge size: Most alternative fuels are available in the mm level; whereas Harden divides the discharge size level into 30mm below, 50mm below, 80mm below and 120mm below according to the modular combination of different processes and according to the customer's needs, which is more user-friendly.

In the context of global carbon emission reduction, all industries are promoting a low-carbon and environmentally friendly green economy, and one of them is the Harden’s SRF/RDF preparation technology. It can be used to process industrial waste from daily life and industrial production, and then through an integrated process and continuous innovative research and development, it can be used to produce better SRF/RDF fuels to gradually replace the use of fossil fuels and achieve a new ecology of carbon reduction and economic benefits.