2023-03-10

2023-03-10In recent years, alternative fuels have been heating up rapidly, and major cement enterprises and fuel power plants are all laying out alternative fuel production bases. So how do we choose or prepare better alternative fuels?

Smaller discharge size? Less moisture contents? More pure ingredients?

Can not chase the extreme effect, but also count the balance of economic benefits, is the best choice for enterprises.

First of all, what is a good alternative fuel?

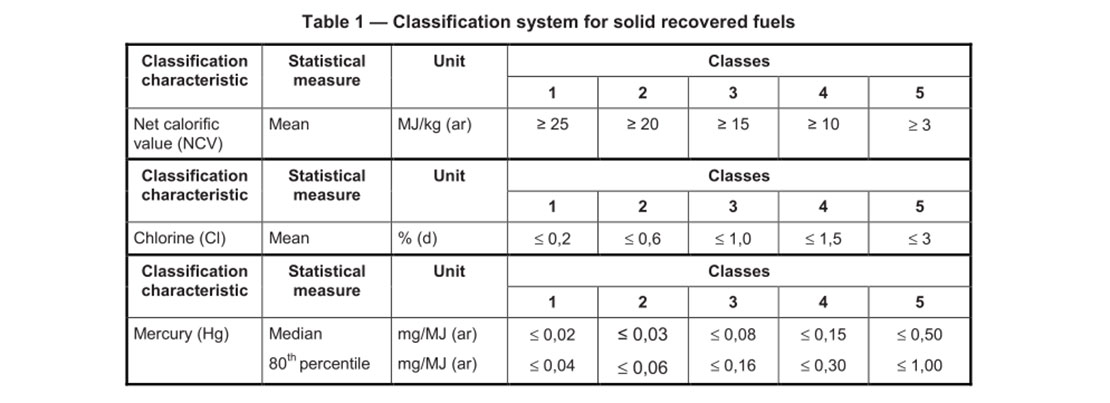

There is a European standard BS EN 15359-2011, which classifies solid recovered fuel (SRF) into five grades of quality. SRF refers to solid recovered fuels, which are non-toxic and include municipal solid waste, general industrial waste, commercial waste, sewage sludge and other components such as wood, paper, fabrics, plastics and rubber.

The three indexes are: ① low calorific value LHV; ② chlorine content; ③ Mercury content.

So, based on the development of the alternative fuel market, which alternative fuels should we choose now? The following is a guide to alternative fuel pretreatment technology and economic benefits, with you to analyze what alternative fuel is better quality.

1、The moisture content of alternative fuel

The evaporation of water in the alternative fuel will result in heat loss carried away by the flue gas at the preheater outlet, which will make the higher the water content of the alternative fuel, the lower the heat value. So the lower the water content of the alternative fuel, the better.

The refuse-derived fuel made from municipal solid waste (MSW):

2、The discharge size of alternative fuel

The large size of alternative fuels means they burn much more slowly than fossil fuels like pulverized coal. So the smaller the alternative fuel, the better?

In fact, there is also a cost of shredding size and efficiency, the smaller the discharge particle size, the longer it takes and the lower capacity per hour. Therefore, when the discharge size and capacity of shredding are taken into account at the same time, the economic benefit will be maximized.

The refuse-derived fuel made from industrial waste:

3、The composition of alternative fuel:

Solid waste such as wood, paper, fabric, plastic, rubber and so on have different calorific values, and most solid waste contains heavy materials such as metal, soil and so on. If the material is not treated or the treatment result is not ideal, the calorific value of the prepared alternative fuel will fluctuate greatly, thus affecting the burnout rate and thermal efficiency, and losing 30 to 40 percent of the heat.

In fact, we can't change the calorific value of raw materials. The recycling prices of different raw materials are different in the market, and some can also charge cleaning and handling costs. So it is particularly important to choose a better preparation and treatment process to remove non-combustible substances and metals in solid waste.

The refuse-derived fuel made from bulky waste:

4、Carbon reduction ratio of alternative fuels:

Every industry that uses a lot of energy has targets for energy efficiency constraints and energy conservation and carbon reduction. According to the carbon emission factor in IPCC guidelines, the waste oil is 74 kgCO2/GJ; Tire 85 kgCO2/GJ; Plastic 75 kgCO2/GJ; Waste solvent 74 kgCO2/GJ. That is to say, the use of plastic solid waste related as an alternative fuel can reduce carbon emissions by more than 20%.

The solid recovered fuel made from industrial waste:

Harden has been deeply engaged in solid waste treatment industry for more than 10 years and has a technical background, mature process and successful project cases in the fields of municipal solid waste (MSW), bulky waste, paper mill waste, stale waste, industrial waste, waste tires, agricultural and forestry waste.

The Solid Recovered Fuel (SRF) and Refuse-derived Fuel (RDF) Preparation System

Moisture content: ≤5%、≤15%、≤25% (different moisture content among different raw material);

Discharge size: ≤30mm、≤50mm、≤80mm、≤120mm;

Preparation process: double shredding, magnetic separation, wind separation, sorting, dust removal, granulation and other preparation process, the equipment is highly innovative and self-developed, can be free modular combination.

No matter the municipal solid waste with high water content or the industrial solid waste with various components, Harden always adheres to the customer orientation, starting from the dimensions of material size, production efficiency, preparation technology and other aspects to develop more in line with the customer's economic benefits of integrated solutions through the free combination of modular, integrated and automated equipment.

Solid recovered fuel (SRF) or refuse-derived fuel (RDF) preparation from solid waste is a new gateway under the background of carbon neutrality. Through SRF/RDF preparation system, better quality and more economical alternative fuel can be prepared. It is not only economical and practical, but also an effective way to realize low carbon, environmental protection and emission reduction in all walks of life.