2024-12-19

2024-12-19As global environmental challenges and resource limitations grow more severe, effective management and resource recovery of solid waste have become critical concerns for nations worldwide. In the context of pursuing "carbon neutrality" objectives, the pressing tasks of recovering resources, safely processing, and reducing the volume of municipal solid waste, construction materials, and other types of solid waste require prompt attention.

In this scenario, the importance of solid waste screening technology has become increasingly significant. This article will discuss the importance of solid waste screening, the obstacles encountered, and specifically emphasize how Harden Machinery's independently developed vibrating screening equipment aids in the efficient resource utilization of solid waste.

Addressing the Challenges of the Solid Waste Screening Process

The screening process for solid waste encounters a variety of challenges due to the diverse and intricate nature of its sources. Different types of solid waste come from numerous origins, necessitating the separation and classification of complex materials during processing.

For example, putrescible waste is often high in moisture and sticky, which can lead to blockages in screening machinery. Additionally, renovation waste typically contains multiple materials (such as soil and gravel), making it challenging for conventional screening equipment to achieve high exclusion rates.

Additionally, the diversity of household waste presents its own challenges, as it consists of many types, is often highly humid, and can adhere to surfaces, complicating resource utilization efforts. Effectively separating recyclable materials is a complex and vital task.

In the waste treatment and recycling process, efficient classification is critical for separating different elements within waste streams, recovering valuable materials, minimizing the amount sent to landfills, and finding new uses for recyclable materials.

In urban waste management, solid waste is generally categorized into four main groups: source reduction and reuse, recycling, energy recovery, and treatment and disposal. Screening plays a crucial role in the material recovery and recycling process of waste management.

Upon arrival at recycling facilities, waste must be screened to better manage these materials. Once materials reach the recycling facility, they are typically classified through multiple separation methods, and screening equipment is essential in this process. Rotary tumbler screens and various vibrating screens are the most commonly used screening machines today.

Functions and Benefits of Screening Equipment

Screening equipment performs material classification by separating larger items (such as cardboard and large plastic containers) from smaller items (like metal waste, glass fragments, and small plastic waste), significantly enhancing resource recovery rates. Effective screening is essential not only for environmental management but also for improving operational economic performance.

In Material Recovery Facilities (MRFs), material flows are often inconsistent, causing sorting robots and optical sorters to rely on a continuous and consistent supply of materials. The role of screening is to homogenize material flow, reduce flow depth, and thus increase downstream equipment efficiency to ensure sorting operations are more effective and consistent. Screening technology optimizes sorting decisions via precise material classification, enhancing productivity, ensuring that the correct materials reach the correct sorting stations, and ultimately improving overall throughput and efficiency.

Exceptional Performance of Harden Machinery's Screening Equipment

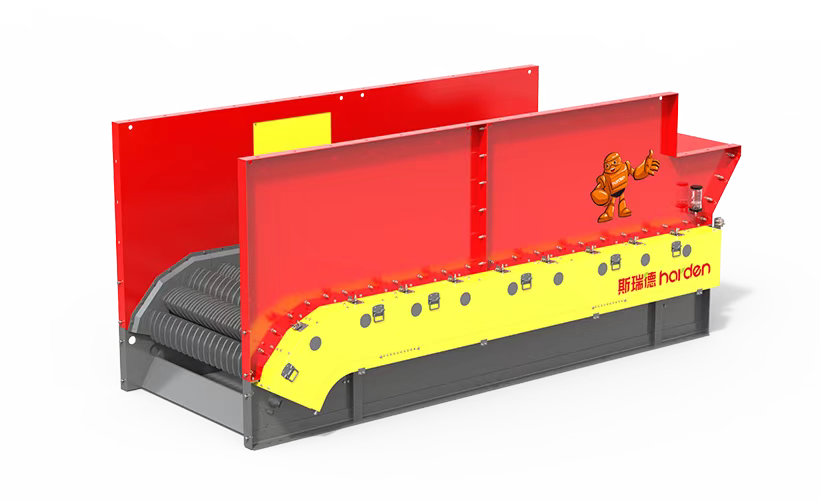

Flip-flow Screen - Addressing Moist and Sticky Waste

Harden Machinery has introduced the Flip-flow Screen, engineered to proficiently manage high-moisture and sticky solid waste. Its vibrating system comprises a fixed screen frame and a moving screen frame, operating through their relative motion. The screen surface oscillates at a high frequency, producing substantial acceleration that effectively resolves issues of screen hole blockages.

Step Screen - Precise Screening of Complex Waste

To tackle the complexity of renovation waste, Harden Machinery developed the Step Screen, which features a stepped sieve design. As the material passes through, the device produces a three-dimensional motion during the material's descent, allowing smaller items to fall continuously through the screen mesh while larger items are expelled from the screen surface, achieving precise screening results.

Composite Screen - Multi-Level Material Separation

The Composite Screen combines the advantages of the Flip-flow Screen and the Step Screen, enabling it to handle complex and high-moisture solid waste. This device utilizes an excitation source to drive the upper and lower screen plates to create different movement formats, effectively separating materials of different sizes to meet multi-level high-efficiency processing requirements.

Triangular Rotary Screen - Designed for Screening Low Viscosity and Moisture Content Materials

The Triangular Rotary Screen is an advanced screening device featuring several patented technologies and a modular design, tailored to accommodate various screening particle sizes. This equipment boasts low energy consumption, minimal noise, high efficiency, and a significant screening throughput rate, positioning it at the forefront of screening technology. It finds applications in the processing of primary domestic waste, household waste, construction debris, biomass derived from kitchen waste, industrial waste, waste rubber tires, and other materials.

Disc Screen - Efficient Separation of Materials through Polygonal Disc Motion

Harden Disc Screen is a screening device that separates materials of different particle sizes and shapes through the rolling motion of polygonal discs. As all the polygonal discs rotate in the same direction as the drum, the material undergoes a composite movement of horizontal and rolling motion on the disc surface, which helps to loosen it. Under the impact of the rotating discs, the material experiences impact, diffusion, jumping, and rolling motion. As a result, particles with a diameter smaller than the gap between the discs fall through the gaps on the side, achieving the desired screening effect.

Intelligent and User-Friendly Design

Harden Machinery’s vibrating screening equipment incorporates various modern electrical automation technologies, including modular structural design and intelligent control systems, allowing for rapid adjustments of vibration parameters based on material characteristics while enhancing the flexibility and operational efficiency of the equipment. Additionally, the double-shock isolation technology effectively reduces vibrations' impact on the surrounding environment, resulting in more stable and reliable equipment performance during operation.

In light of the challenges posed by urbanization and population growth, the efficient treatment and resource utilization of solid waste has become an unignorable task. Harden Machinery's screening equipment plays a crucial role in the solid waste screening field with its outstanding technology and design. Looking ahead, as the emphasis on solid waste resource utilization continues to grow, screening technology will play an increasingly vital role in waste management. Effective screening technology not only makes solid waste treatment more efficient and economical but also opens up new avenues for resource recycling.