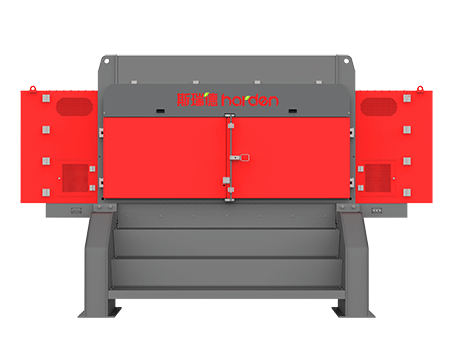

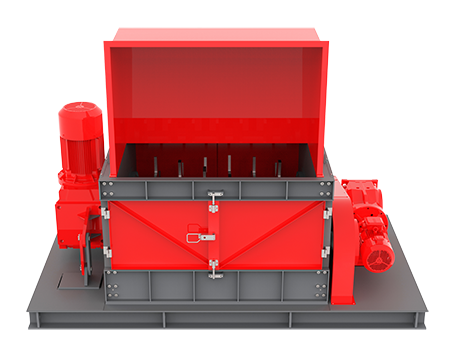

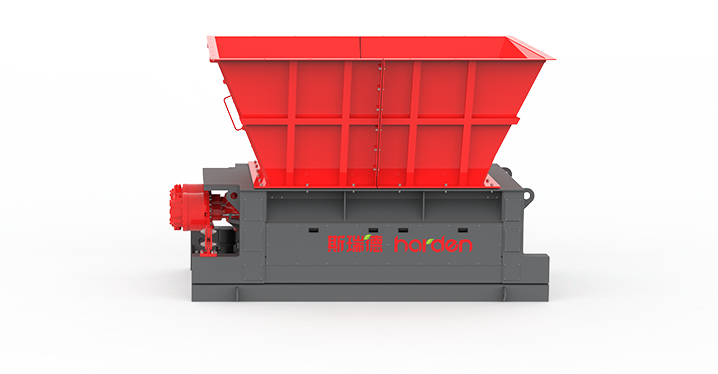

The primary shredder developed by Harden, driven by hydraulic power and designed for large-scale operations, is robust, long-lasting, and requires minimal maintenance. It is specifically intended for reducing the size of large materials and pre-shredding solid waste. With multiple shredding mechanisms including shredding, chopping, tearing, and squeezing, it effectively handles mixed solid waste containing complex components such as unsorted municipal waste, construction debris, and industrial waste.

Furthermore, Harden’s primary shredder produces waste particles of relatively uniform size, facilitating material separation and recycling in subsequent processes. This enables the retrieval of recyclable materials or the production of high-calorific refuse-derived fuel (RDF). Additionally, the primary shredder can be repurposed as a bag breaker through the replacement of cutters.

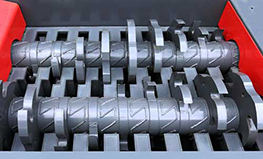

High wear-resistant | Cutter edge welding

Withstand high pressure impact | Patented weld protection technology

Offset shaft torque | Bearing stress filter | Vibration reduce

| Model | TPH1026 | TPH1620 | TPH1826 |

| Motor Power(KW) | 132-200 | 132-250 | 250-400 |

| Rotating Speed(RPM) | 17-58 | 17-58 | 17-58 |

| Cutting Chamber Dimension(A*B) (mm) | 1000X2600 | 1600X2000 | 1800X2600 |

| Machine Dimension(L*W*H) (mm) | 5000X1550X1200 | 4400X2100X1060 | 5000X2350X1200 |

| Cutter Quantity(PCS) | 9-11 | 14-18 | 18-22 |

| Throughput(T/H) | 15-40 | 20-50 | 30-80 |