Product introduction

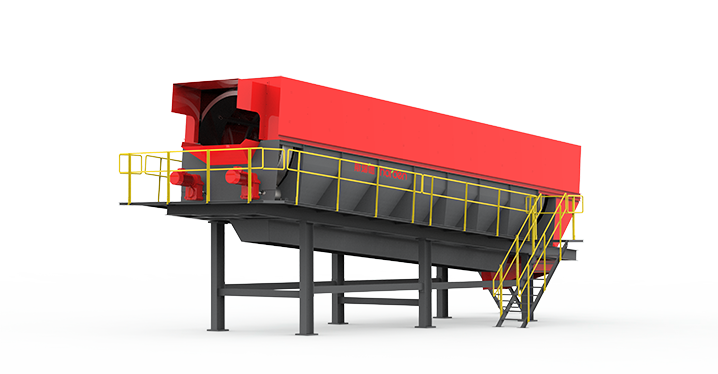

Harden’s drum screen consists of a motor, reducer, rolling equipment, rack, sealed cap, inlet, outlet, and more. The rolling equipment is mounted on the rack at an angle, with the motor connected to the rolling equipment via a reducer and coupling, which drives the rolling equipment to rotate on the coupling. As material enters the rolling equipment, it flips and rolls on the screen surface due to the tilt and rotation of the drum screen. Undersized material is discharged at the bottom of the drum, while oversized material is discharged at the end. The continuous flipping and rolling motion of the material in the drum prevents it from getting stuck in the mesh screen, effectively preventing blockages.

Scope of application

Sorting cases

Product parameters

| Name | Roller |

| Throughput | 15-80 |

| Motor Power | 2.2 |

| Roller Screen Diameter | 600mm |

| Roller Screen Length | 1800mm |